FIRST THE BAD BIT ..... January

21st 2006 There is a knock at the door and the

mailman is stood there with a HUGE parcel. It can only be

one thing... the TQ has arrived from Symulatory in Poland!

I have saved long and hard for this and of course I am really

excited. The Original Cost was 1270 euro's plus

shipping. So slowly I open the package in anticipation and

to my horror the TQ is damaged, i'm devastated. The no.2

throttle lever is broken and the TQ body does not seem to be

'square'. I also have ordered some replacement parts

which were broken on the last delivery and even these are broken

again. I am so angry and disappointed.

NOW THE GOOD BIT .... ALL's

WELL THAT ENDS WELL WOW I have

it working well and it looks the part too and it impresses the hell

out of everybody

who has seen it even real 737 pilots who come to play :o)

Simply click on a thumbnail

and we'll take a walk round it. OK, first and foremost we have a seperate

throttle for each engine. Keeps you on your toes when taxiing

because of asymmetrical thrust. Then the Flaps

Lever is so realistic. You do have to spend a little time

setting it up for accuracy so that the amount of flaps set corresponds

with the detente. But that said, mine runs very accurately now

and the flaps deploy exactly where they have been commanded to.

Thirdly is the Spoiler Lever, again some

accuracy is required here. I spent quite a bit of time getting

this accurate. First of all i played around with sensitivities

in FS and then 'fine tuned' the axis in FSUIPC. Now I can use

the Spoiler in flight and return it to the down position, no

problem. The satisfaction on Landing and using the Thrust

Reverse Levers is great, especially when your Virtual

Co-Pilot in Flight Deck Live tells you 'Reverse Thrust Engaged' and

'Reverse Idle' - AWESOME.

Add to this the fact that the TOGA, A/T Disconnect, Fuel Valves and

Parking Brake have been introduced into the cockpit as hardware

controls makes for a very realistic addition to the whole

experience. The CPFlight MCP and the SYMULATORY Throttle

Quadrant are the two most important purchases I have made.

How it all works is quite simple really. Imagine your

joystick, it has several axes which are assigned to different

functions, the most common being the Ailerons, the Elevators and the

Throttle. Well these axes can be assigned to any of the

functions that require an axis to drive it. So, the TQ has

six potentiometers built into it. Each throttle lever has one,

each reverse thrust lever has one, the Flaps Lever has one and finally

the Spoiler Lever has one. Originally, i connected the TQ to the PC

via the Opencockpits Joystick Emulator. But sadly this card only

offers you 5 axes. A step by step guide on how to connect your

TQ using a Joystick Card is on the left.

Then I came across the BU0836

Controller from Leo BODNAR. This card in it's native state

can control upto 8 seperate axes and gives you the expansion of 32

extra joystick buttons and a Point of View Hat if you need it.

PLEASE

NOTE! If you use FSUIPC, it will only see the first 6

axes, but that's OK, it's all we need. I have built the

BU0836 card into the TQ and here's what it controls.......

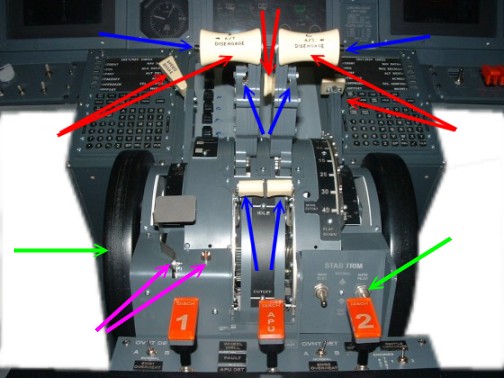

RED

ARROWS

are all axes and are assigned as follows:

No 1 is Throttle 1. X

Axis No 2 is Throttle 2. Y

Axis No 3 is Reverser 1. Z Axis

No 4 is Reverser 2. X Rotation No 5 is Spoiler. Y

Rotation No 6 is Flaps Lever. Z Rotation

All Axes have

been assigned and calibrated in FSUIPC

BLUE

ARROWS are all connected to the BU0836 Joystick Buttons Matrix. Then

the button is read in FSUIPC and then the command sent to the sim to

action that command.

PURPLE

ARROWS The

Parking Brake and the Annunciator are connected thru the CPFLIGHT

MCPEX1 which gives me an accurate On/Off state

GREEN

ARROWS Elevator Trim. is controlled by a clever little

component called a PULSE SWITCH. It is basically two rotary switches

in one and only contacts momentarily at each detente in the direction

of rotation. Connected to Leo's Joystick Card as two seperate buttons,

rotating it has the same effect as constantly pressing a joystick

button. In FSUIPC the buttons are assigned to Elevator Trim Up

and Elevator Trim Down. So rotating the trim wheel works.

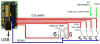

Symulatory build in two gears on the trim shaft (one drives a rotary

encoder which i have replaced with the Pulse Switch). The wiring to

the Pulse switch is routed via the STAB TRIM switch to give me a Man

and Cut Out position. Also going to route the Yoke Trim Switches

thru the other one, so i have Man Elec and Cutout. See the diagram. GREEN

ARROWS Elevator Trim. is controlled by a clever little

component called a PULSE SWITCH. It is basically two rotary switches

in one and only contacts momentarily at each detente in the direction

of rotation. Connected to Leo's Joystick Card as two seperate buttons,

rotating it has the same effect as constantly pressing a joystick

button. In FSUIPC the buttons are assigned to Elevator Trim Up

and Elevator Trim Down. So rotating the trim wheel works.

Symulatory build in two gears on the trim shaft (one drives a rotary

encoder which i have replaced with the Pulse Switch). The wiring to

the Pulse switch is routed via the STAB TRIM switch to give me a Man

and Cut Out position. Also going to route the Yoke Trim Switches

thru the other one, so i have Man Elec and Cutout. See the diagram.

BACKLIGHTING Straight from the manufacturer, there is no provision for

backlighting. However i saw on a Norwegian Builders site a very

clever Idea. What he did was to use flexible striplights like

you see in cars. This is something I have investigated. In

the end I have used a couple of simple MES Bulbholders with 12v bulbs

powered from a simple PC Power supply (See the Components Page).

AUTOMATION. I am

investigating the options open to me for automating the Throttle

Levers, Spoiler and Trim Wheels. At Present, the favourite

is PHIDGETS, but that could change.......(added

11th Sept 2009, EVERYTHING HAS :o))

)

LET's

LOOK INSIDE IT

Ok, basically it has 5 inner panels held together by a series of

positioning blocks which are machined and jointed to hold the plates

in place. 4 potentiometers are situated inside the assembly for the

two throttles, the flaps lever and the spoiler lever. It's real

clever how it all fits together.

Thru

the centre runs a 10mm Threaded Rod. This is what the Trim

wheels bolt onto. It sits in two roller bearings inside the side

covers to support it either end. Now here's the clever

bit. The rod runs inside a polished steel tube onto which the

handles/levers rotate. A second tube is situated also inside the

assembly on which the idler or transfer gears rotate.

|

HAVING

PROBLEMS WITH SYMULATORY? HAVING

PROBLEMS WITH SYMULATORY?

You are not alone. Sadly things in

Andrychow seem to have gone from bad to worse. Several colleagues

have been telling me about their bad experiences and they read

like a Horror Story. If your email is ignored try this

one:

biuro@symulatory.com

or here's the phone no. 0048338753776

and if that doesn't work here's their address:

JAKUB GAIK

ul.Żwirki i Wigury 2

34-120 ANDRYCH”W

POLAND

|

SYMULATORY

Throttle Quadrant.

I have the USB version. This controls

the various operations by the use of axes. For full

functionality, you need 6 axes as follows.....

1. No 1 Throttle

2. No 2 Throttle

3. Spoiler

4. Flaps Lever

5. 2 Thrust Reversers.

and 4 buttons for....

Capt.& F/O TOGA Buttons (tee'd)

Capt.& F/O A/T Disconnect (tee'd)

No.1 Engine Fuel Valve

No.2 Engine Fuel Valve

In FS the Parking Brake is a toggle, so it

just reverses the state of the Parking Brake. I have actually

wired this switch thru the CPFlight MCPEX board so that i have

an ON and Off state and used one of the outputs to give me the

Indicator Lamp. But for those who don't have this

function, i suggest fitting a second micro switch to allow an

On/Off state to be obtained in FS.

First of all I deleted the axes assignments in FS2004 then

assigned and calibrated them finally in FSUIPC.. The result

is very good. The throttles are very responsive from the rest

position. The Spoiler reacts exactly where the indications

are on the Quadrant Housing and most accurate is the Flaps Lever

which deploys the correct amount of Flaps at the Correct detente

in both the extending and retracting directions. Fine tuning

does take a little bit of 'pissing' about with, but it sure as

hell is worth it.

Symulatory

TQ Wiring Diagram

PMDG737

Idle/Cutoff Levers

I've discovered that it

is possible to accurately control the Idle/Cutoff Levers on the

PMDG by manipulating the offsets. These levers respond to

the FS commands for the Fuel Valves. in the FSUIPC Buttons and Switches Menu, in the FSCONTROL dropdown Menu is an item Offset Byte Set. this is where it's at. the

offset for Eng 1 Fuel valve is 3590 and for the Eng 2 Fuel Valve is 3594 (don't know if this works with the 747, but Eng 3 is 3598 and Eng 4 is 359C). setting the parameter (based on your switch) will give you an accurate on/off state of the levers. parameter 1 for valve open and 0 for valve closed.

This only works with continuosly on switches (toggle or microswitch) and not with pushbuttons i'm afraid.

Simply select your button or switch and let FSUIPC identify it. select the Offset Byte Set item, change the

ofset to x3590 for eng1 (or the offset for the engine valve you want to control) and put a zero in the parameter box if you want the valve closed when the switch is closed (or vice versa). then go down to the 'when button released' section and reverse the parameter.

See HERE

PARKING

BRAKE...(added 24/12/2008)

The same technique used on the fuel valves (in FS9.1) can also be

applied to the Parking Brake using Offset 0BC8. Parameter 1 = Parking

Brake On, Parameter 0 = Parking Brake Off :o))

|

|