|

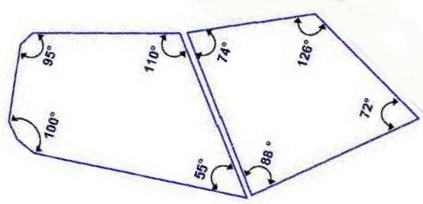

OK, how do you turn this drawing into a B737NG side window

assembly easily? Quite simply you don't. The Windshield assembly is

the most complex part of the shell, so I decided to start there.

What I did was to build a basic frame using straight angles and I will

'round' the two back window angles using the trim sheets.

OK, so it's June

2006 and now i

want to build the Shell.

My

original plan was to start at the back and work forward, but I

soon found my plan was 'flawed' because of space constraints, so

i started experimenting with Panel Positions, Angles and getting

the look right. Ok, i admit it looks awful, but the result :o))

The reason I have included 'Warts & All' photo's is this is a

pictorial record and these were the experiments to get it looking

right.

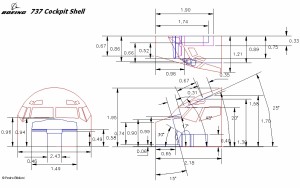

July

2006, armed with a drawing, a pile of wood and some

tools, I set about trying to create a masterpiece like the one

in the top right image. I

should have gone to the Pub !. If anybody tells you that

building the windshield and side windows of a Boeing 737NG

is easy, don't believe a word of it, it's a B*****D !. I

know, i've been there. But dogged determination and

a will to succeed gets you going in the right direction.

Electronics, Computers and Technology do not defeat me, but I

have to take my hat off to you guys who can master the art of

shaping wood into sophisticated art forms that your wife doesn't

want to light the barbeque with. July

2006, armed with a drawing, a pile of wood and some

tools, I set about trying to create a masterpiece like the one

in the top right image. I

should have gone to the Pub !. If anybody tells you that

building the windshield and side windows of a Boeing 737NG

is easy, don't believe a word of it, it's a B*****D !. I

know, i've been there. But dogged determination and

a will to succeed gets you going in the right direction.

Electronics, Computers and Technology do not defeat me, but I

have to take my hat off to you guys who can master the art of

shaping wood into sophisticated art forms that your wife doesn't

want to light the barbeque with.

So, two litres of blood later and some swear words i didn't know

i knew, we are getting somewhere. Out of nowhere ,

miraculously has appeared a shape that resembles the two front

windshield panels. I may have been a little

over zealous with the centre support, but it has to support a

lot of weight. And of course there's still time to change the

design.

August

2006 Managed

to get the windshield off the ground and mounted. To my surprise

it all actually fits. Now i know the physical dimension of the

Front/Rear Overhead combination and with

these in hand, i made the

frame to hold them and got that fitted. So the basic framework

is starting to take shape. I have one eyebrow window trim, so

this made mating it all up much easier and of course the  right side is

going to be a mirror image of the left. Now I feel like i'm

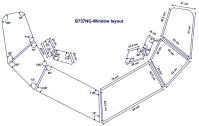

getting somewhere. Preparation is everything, so i spent the

rest of the year looking over what drawings i could find to formulate

a plan. I based most of my dimensions and angles from the

drawings on this page (more on the TECHNICAL

page) . But A Word Of Advice, you have to

be 'artistic' with the dimensions/angles to get it all to fit together

properly. This took me thru into the spring of 2007. right side is

going to be a mirror image of the left. Now I feel like i'm

getting somewhere. Preparation is everything, so i spent the

rest of the year looking over what drawings i could find to formulate

a plan. I based most of my dimensions and angles from the

drawings on this page (more on the TECHNICAL

page) . But A Word Of Advice, you have to

be 'artistic' with the dimensions/angles to get it all to fit together

properly. This took me thru into the spring of 2007.

April

2007 The shots

above are basically where we have got to by this time. The basic frame

work is up and I'm just 'tweaking' the last angles and dimensions

before I screw and glue it all in. At this April

2007 The shots

above are basically where we have got to by this time. The basic frame

work is up and I'm just 'tweaking' the last angles and dimensions

before I screw and glue it all in. At this  point, I think it's

worth mentioning that a cockpit shell has quite a lot of weight to

to. My best guess is the weight of the wood, cables,

brackets and light fittings is somewhere in the region of

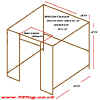

60-70kg. So I decided to build an 8 feet (about 2.5mtrs) outer

frame to give me some support for the weight. Secondly, there

are so many cables and wires, i fitted plastic conduit along the beams

to run the cables in. Great idea, but I still have a plate of

spaghetti behind the frame because i point, I think it's

worth mentioning that a cockpit shell has quite a lot of weight to

to. My best guess is the weight of the wood, cables,

brackets and light fittings is somewhere in the region of

60-70kg. So I decided to build an 8 feet (about 2.5mtrs) outer

frame to give me some support for the weight. Secondly, there

are so many cables and wires, i fitted plastic conduit along the beams

to run the cables in. Great idea, but I still have a plate of

spaghetti behind the frame because i

can't get in there

:o)) The frame is constructed from basic wall batten

bolted together. I am constrained to a width slightly over 3mtrs

and a height which is basically the same, so positioning of the

projectors is vital so I can A. Fill the screen and B. not have

cockpit shell parts 'shadow' in the beams. I also have an

electric door on the garage, so I have had to work around the frame

for that as well. Finally, looking above the cockpit

entrance, I can't get in there

:o)) The frame is constructed from basic wall batten

bolted together. I am constrained to a width slightly over 3mtrs

and a height which is basically the same, so positioning of the

projectors is vital so I can A. Fill the screen and B. not have

cockpit shell parts 'shadow' in the beams. I also have an

electric door on the garage, so I have had to work around the frame

for that as well. Finally, looking above the cockpit

entrance, I have built a 'Services Shelf' to supply Mains Power and to

house the

Power Supply Units for 12v and 5v d.c. distribution to the

Overhead Panel and MIP. have built a 'Services Shelf' to supply Mains Power and to

house the

Power Supply Units for 12v and 5v d.c. distribution to the

Overhead Panel and MIP.

August to

October 2007.

This time was spent building the roof and Trimming Out the Flightdeck....I

was looking for a realistic shape to the roof and I just couldn't get

it right. I'm governed by the shape and size of the Eyebrow

Windows on the bottom and the size/shape of the roof at the back where

it meets the Overhead Frame. I was 'stumped', couldn't get

it right. Then purely by chance I was returning from holiday and

stood at a baggage carousel. Seen how the slats turn a

corner? BINGO, got it.

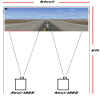

PROJECTORS

At the time of writing, I have two

ACER 1260 Projectors hooked up tru a DualHead2Go. What this

allows me to do is simply by altering the desktop properties is to

switch between either of the images seen here. Because of space

constraints, i cannot use 3 projectors to have a Left Side (at 45

degrees),CENTRE and Right Side visual system. But again given

the positioning restraints, i cant get a single projector to fill the

centre view. So you have to give and take a little. PROJECTORS

At the time of writing, I have two

ACER 1260 Projectors hooked up tru a DualHead2Go. What this

allows me to do is simply by altering the desktop properties is to

switch between either of the images seen here. Because of space

constraints, i cannot use 3 projectors to have a Left Side (at 45

degrees),CENTRE and Right Side visual system. But again given

the positioning restraints, i cant get a single projector to fill the

centre view. So you have to give and take a little.

|